Advanced Materials Research

At the Tennessee Center for Renewable Carbon, we are involved in the development of technologies that will foster the use and economic viability of materials, chemicals and fuels derived from renewable sources for a sustainable and more secure future.

A description of our research focus is below. Learn more about our research and equipment capabilities or access selected research publications.

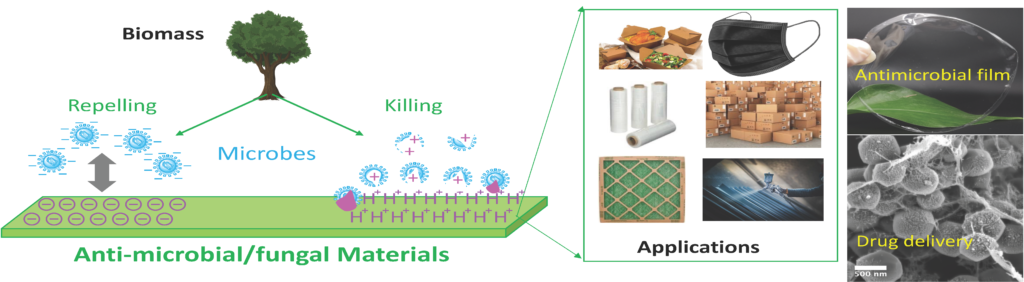

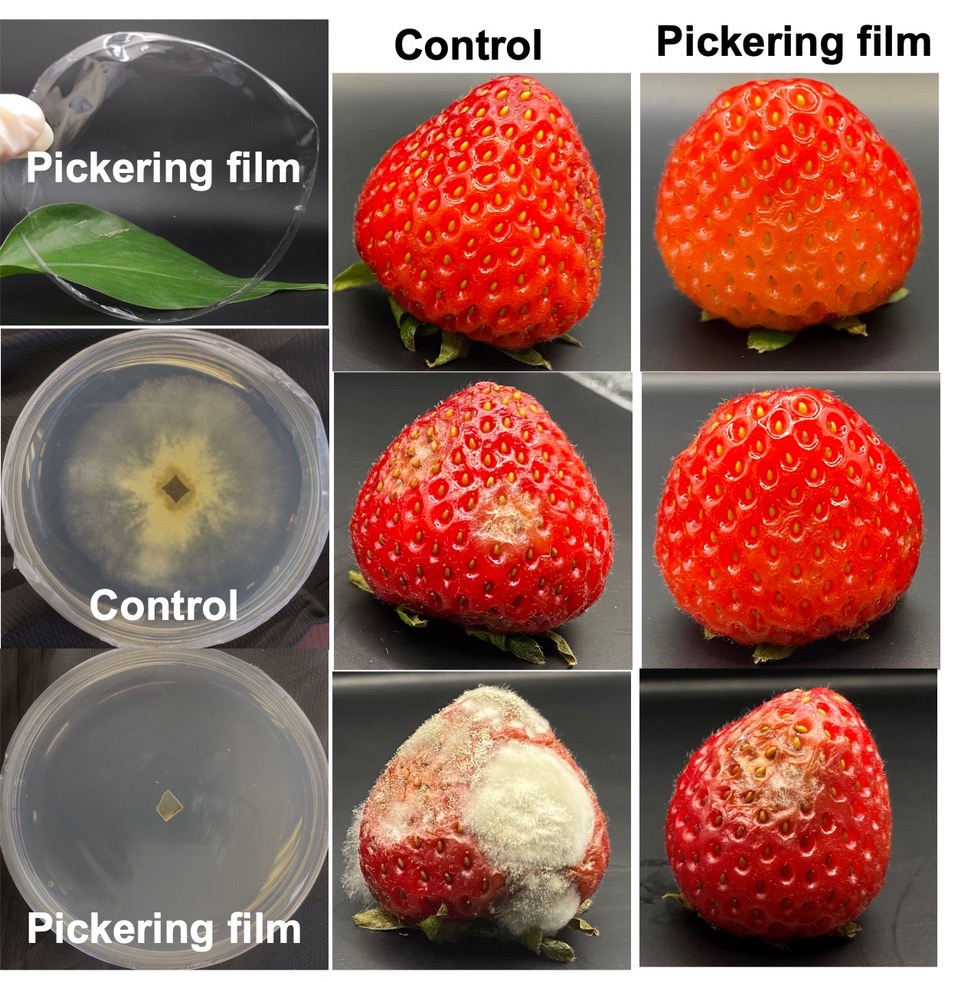

Designing and Engineering Bio-derived Antimicrobial Materials

The rapid global spread of COVID-19 and other emerging diseases emphasizes the need for preventative measures to curb disease transmission, especially in agricultural and food systems. Workers in the Li lab are developing a novel type of nanocellulose-based, self-disinfecting material to reduce microbial contamination on surfaces. Special functional groups are introduced to realize dual sanitizing effects—repelling microbes through negative charges and killing microbes through local surface acidity. The designed self-disinfecting materials can be rapidly and widely applied to the coating of packaging materials (paper, board, containers), personal protective equipment (face shields, masks), and high-contact surfaces (door handles, elevator buttons, public transportation surfaces, cellphone cases), replaceable films, composites, textiles, and biomedicals. This project will demonstrate a new approach beyond the current technical capacity for bio-derived, value-added nanomaterials, which will improve long-term sustainability of the US agricultural and food systems. These materials will help significantly curb food spoilage/contamination and spread of infectious diseases in agricultural and food systems, at a time when these systems are already under the constraints of a growing population, climate change, natural resource depletion, and the energy crisis.

Developing Advanced Nano Materials Using Biomass as Raw Materials

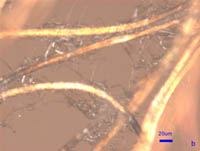

Lignocellulose based nanomaterials have been widely researched for many years, and cellulose is also a useful biomass component for many applications. Researchers in the Wang lab have developed several techniques to manufacture cellulose nanofibers and explore their applications. Recently we have started exploring lignin based nano particles, processing cellulose and lignin solid into lignin contained cellulose nanofibers and demonstrating a few unique applications such as superhydrophobic coating.

The utilization of hemicellulose (typically 5-carbon sugars) is still the bottleneck of the current biorefinery industry. To utilize the hemicellulose sugar stream, an effective hot-water pre-extraction and carbonization strategy of lignocellulosic biomass was introduced to synthesized fluorescent carbon dots (CDs) with tunable photoluminescence (PL) intensity and quantum yields (QYs) without carbonization of the entire biomass. No additional doping agent was used according to an innovative bio-refinery concept. The yields of de-branched sugars in hot-water extractions can be adjusted with increasing temperature between 120–180 ºC, thereby leading to distinct N-doping CDs after high temperature carbonization (220 ºC for 5 h).

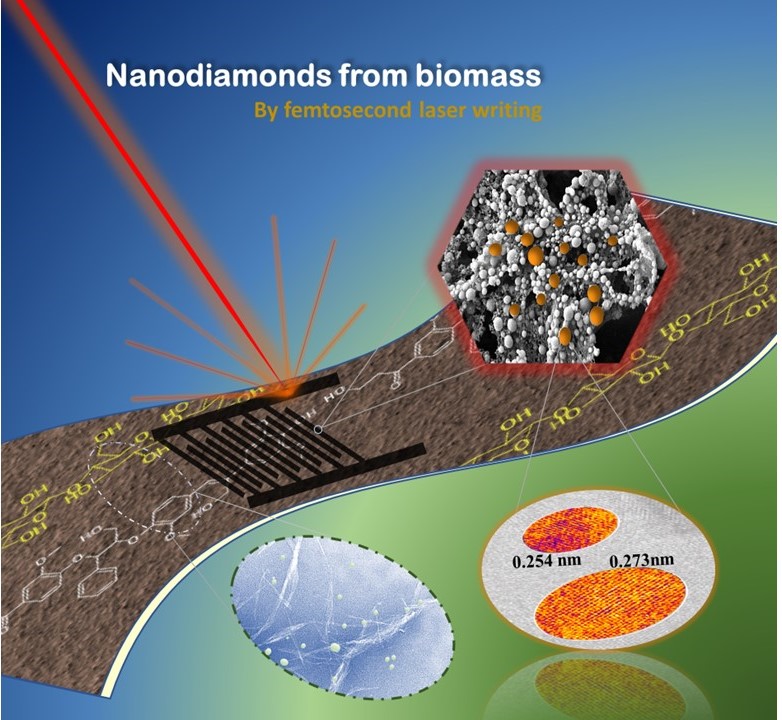

Commercial nanodiamonds (NDs) are usually produced by detonation and chemical vapor deposition. While these methods normally require either the application of extreme temperatures/pressures or expensive and hazardous gaseous/chemical precursors, in our recent study, NDs were produced on paper made from nanolignin/cellulose nanofibrils (LCNF) composite film by means of direct laser writing at ambient temperature and air pressure. The generation of NDs was found to depend largely on high laser power. Graphene nanoribbons and carbon nanoonions were obtained at lower laser power as acceptable products. As cellulose nanofibrils were unsuccessfully lased in this study, the effects of diverse components of LCNFs were investigated. Results showed that a suitable cellulose content in LCNFs can accelerate laser carbonization, while an excessive oxygen content component will lead to the combustion of LCNFs in air. Moreover, it was found that a higher lignin content was essential for the formation of NDs. Individual nanolignin particles were successfully converted into NDs.

Exploring Wood/Biomass Science and Technology and Wood-Based Composites Using Nano Mechanical Testing as a Key Tool

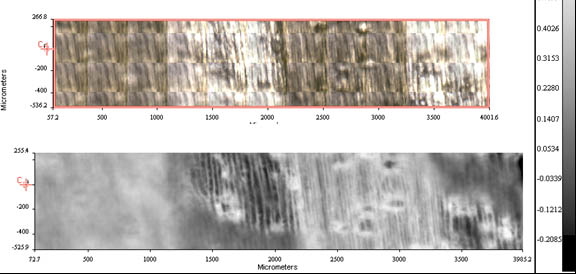

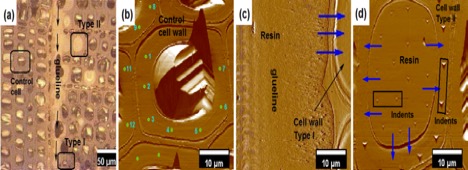

It is hard to find new furniture made without adhesives. Understanding and controlling the chemical and mechanical properties of wood-adhesives bondline at sub-micrometer spatial resolution is critical to accelerate the development of high-quality wood-based composites. The Wang lab has developed and/or applied nanotechnology to understand biomass (wood, bamboo, grass), bondline, interphase and adhesion in biobased composites. We have applied nanotechnology to understand nanodimentional structure, chemistry and properties of wood-based materials and the materials used in conjunction with wood (adhesives, coatings and preservatives). For example, we have combined atomic force microscope infrared spectroscopy (AFM-IR) and nanoindentation measurements to identify the specific molecular-scale interactions between phenol-formaldehyde resin (PF) and wood cell wall on the bondline for the first time. PF resin molecules not only simply dispersed within the cell wall but also reacted with cell-wall materials, resulting in the increase in the mechanics of wood cell walls. The nanoscale mechanical interlocks formed between resin and wood cell walls might be beneficial to adhesion performance of wood-based composites. We have also attempted a combined technique of in-situ heating and nanoindentation to investigate the mechanical behavior of each phase on the bondline including cell walls and adhesives at elevated temperature. Our recent research investigated the interphase between wood and water-based coating.

Raw Materials Processing and Characterization

At the Center for Renewable Carbon, we are investigating novel methods to process lignocellulosic biomass to increase the value and utility of end products derived from these materials. This effort includes the use of wide range of raw materials that include: different wood species, bark, grasses, and derivatives. A core component to this research effort is to add value to materials prior to processing. This has led to a new center-wide research effort that extracts sugars from biomass prior to utilization in composites. The sugars will be used as a feedstock for fuels and chemicals. The extracted biomass will be inherently more resistant to water uptake and biological attack. In order to utilize lignocellusic materials smartly, it will be critical to fully characterize them especially in the sub-micron or nano scale. On-going researches include measuring nano-mechanical property of raw materials and understanding effects of processing on the mechanical properties of raw materials.

- Raw materials influenced by processing

- Cellulose based nanomaterials

Products Development

The CRC is actively involved in new products development that includes synthetic and natural adhesives for renewable composites, structural building materials, natural fiber-reinforced polymer composites, biodegradable nanocomposites, multifunctional materials. Further, we are developing new technologies for coupling lignocellulosic derived materials with thermoplastic polymers. These polymers are obtained from either synthetic or natural feedstocks. Current methods for modifying interfaces that are under investigation include: electron-beam curable additives, novel ATRP synthesized copolymers, gas phase modification of lignocellulosic substrates, and novel material processing of biomass feedstocks.

- Process and property improvement of OSB

- Carbon fiber from lignin

Materials Characterization

At the CRC, we use a wide array of mechanical, thermal, spectroscopic, and imaging tools to characterize natural based materials. We study the impact of materials processing and feedstocks on performance. We are particularly interested in the characterization of composite interfaces. Currently, we are investigating interphase in natural fiber reinforced polymer composites and the impact of a variety of adhesives on lignocellulosic cell wall properties using chemical imaging, AFM/SThM, and nano-indentation. These advanced techniques are being related to the bulk mechanical and physical performance of materials. In addition, spectroscopic techniques are being developed to rapidly assess materials and model their performance.

- Nano-mechanics

- Kinetics of water vapor absorption