Lignin-derived Carbon Storing Foams for High Performance Insulation

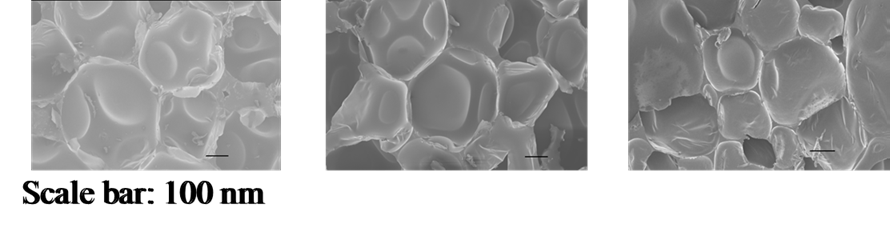

Over the last decade, USA, EU, and industrial interests have significantly advanced the use of bio-derived materials for polyurethanes, including their application for insulating foams. The Ragauskas team has demonstrated that high-quality polyurethane (PU) foams are readily prepared from lignin extracted from biomass. Thus, strengthening the overall operations of cellulosic biorefineries and providing PU foams with improved economic feasibility and environmental performance. The goal of this proposal is to develop higher performance, carbon negative, and eco-friendly lignin-PU foams as a building insulation material via non-isocyanate synthesis. This project focuses on the development of carbon negative material with practically viable performances, competitive market price, and minimal end-of-life emissions as a building insulation. The supporting objectives of this projects are (1) investigating and selecting the optimal biomass feedstock and lignin fractionation method for high-performance and low-cost lignin-PU synthesis; (2) development of an eco-friendly lignin-PU formation via non-isocyanate method; (3) elucidating the characteristics of lignin-PU form and technical performance of the form as a high performance insulation material; and (4) evaluating and delivering a cost-competitive, environmental friendly, and carbon-negative lignin-PU foam production via techno-economic analysis and life cycle assessment. This project outcomes support ARPA-E goals of the development of technologies that nullify embodied greenhouse gas while simultaneously transforming buildings into net carbon storage structures. Furthermore, the development of none isocyanate lignin polyurethane insulation foams directly addresses ARPA-E’s objective of developing develop technologies that, if technically successful, have clear disruptive potential, by demonstrating capability for manufacturing at competitive cost and deployment at scale.